Agenda February 14-15, 2023

Tuesday, February 14, 2023

// 08:45

Welcome & introduction

// 09:00

Welcome by Chair

Sven Wiemer

Schill & Seillacher “Struktol” GmbH

Welcome by Chair

Sven Wiemer

Schill & Seillacher “Struktol” GmbH

› Close Abstract

// 09:00 – 09:25

RELIABLE BOND ON SNOW – STRONG INTERLAMINAR ADHESION IN SKIS

Dr. Raphael Schaller

nolax AG; CH-Sempach Station

› Show Abstract

› Close Abstract

RELIABLE BOND ON SNOW – STRONG INTERLAMINAR ADHESION IN SKIS

Dr. Raphael Schaller

nolax AG; CH-Sempach Station

With the metamorphosis from transportation to sporting equipment, skis have experienced remarkable development over the last 100 years from a materials science perspective. Simple, bulky wooden slats emerged as modern high-performance laminates. The latter comprises different, affiliated materials that ensure driving comfort, performance, and less weight. Moreover, skis should be robust against humidity and temperature fluctuations and have a long service life.

Recently, nolax has explored interlaminar adhesion in skis. A significant challenge for ski manufacturers is joining dissimilar materials with different polarities and thermal expansion coefficients. Moreover, skis are exposed to extensive humidity and temperature changes, which often leads to delamination between the components, especially aluminum and epoxy.

To keep the design and shape and thus the riding comfort of skis, a technique established and used in the automotive industry can improve the adhesion between aluminum and epoxy. Metal sheets are coated first with a thermoplastic high-performance adhesive film before the polymer is rear-injected for manufacturing metal-polymer hybrid components for car interiors. Decrypted to skis, the aluminum top, and bottom chords can be coated first with an adhesive film at elevated temperature and under pressure in a flatbed laminator before further processing in the standard ski manufacturing process. Adhesive films replace labor and time-intensive pre-treatments of the metal surface, such as structuring, roughening, treating with primers, or a combination of these.

With a specific example from the ski industry, we want to show the impact on interlaminar adhesion when high-performance multi-layer adhesive films are used in the ski manufacturing process. Our adhesive film, based on a TPU/PE multi-layer, significantly reduces the failure rate of skis due to good wettability and absorption of stresses caused by different thermal expansion coefficients of the components.

› Close Abstract

// 09:25 – 09:50

RAPID BONDING OF WOODEN MODULES FOR CEILING CONSTRUCTIONS

Tobias Hilse

University of Braunschweig / Institute of Joining and Welding; DE-Braunschweig

› Show Abstract

› Close Abstract

RAPID BONDING OF WOODEN MODULES FOR CEILING CONSTRUCTIONS

Tobias Hilse

University of Braunschweig / Institute of Joining and Welding; DE-Braunschweig

Remodelling and renovating of wooden beam ceilings can become a time consuming and complicated matter: transporting wooden beams longer than the room length through staircases and building up the floor/ceiling layer by layer will be avoided due a novel module-based concept for wooden ceiling constructions. These modules are self-supporting and will be mounted in a staggered pattern utilizing rapid adhesive bondings. First experimental results demonstrated the functionality of this novel technique on small scaled modules and will now be transferred to a bigger, more application-related module size.

› Close Abstract

// 09:50 – 10:15

OPTICAL BONDING - A WHOLE NEW INDUSTRY – CHALLENGES & DEFECTS

Dr. Belinda Berns

SME (subject matter expert) Optical Bonding

› Show Abstract

› Close Abstract

OPTICAL BONDING - A WHOLE NEW INDUSTRY – CHALLENGES & DEFECTS

Dr. Belinda Berns

SME (subject matter expert) Optical Bonding

This speech will be the second part of my new optical bonding presentation series that has started at In-Adhesives conference in May 2022, following up on my very first contribution to MKVS conference back in 2013. Last year you received an overview about optical bonding technology with part one: Optical Bonding - A Whole New Industry - Complex and Highly Demanding. This time I will provide to you some deeper insight into bonding process challenges and possible defects that can occur in this optical highly demanding industry.

Optical Bonding starts already with the right selection of components to be bonded. Besides perfectly clean surfaces of the components itself, also a clean working environment is needed to avoid any particle inclusion. Then, a good knowledge of the selected chemistry is recommended. This is one of the reasons that some do-it-yourself repairs of mobile phones for example at the end are not satisfying in optical appearance. With part one you gained some basic knowledge and saw an overview of this industry sector. Now you will dive deeper into the details. The different chemistries varying in process inherit some specific aspects to pay attention on during the bonding itself.

Interested in more details of this most invisible technology? Come and visit my speech at In-Adhesives conference in Munich February 14-15, 2023.

› Close Abstract

// 10:15 - 10:45

Refreshment Break

// 10:45 – 11:10

BIO-REFINERY DERIVED FURANIC HUMINS AS BASIS FOR SUSTAINABLE THERMOSETS AND ADHESIVES

Tom Claessen

Avantium Renewable Polymers; NL-Amsterdam

› Show Abstract

› Close Abstract

BIO-REFINERY DERIVED FURANIC HUMINS AS BASIS FOR SUSTAINABLE THERMOSETS AND ADHESIVES

Tom Claessen

Avantium Renewable Polymers; NL-Amsterdam

Furanic humins are by-products obtained from carbohydrate valorization processes. Given the large amount of the carbon input that they can contain, they need to be considered as potential new bio based feedstock. In addition, all these product streams, when marketed at their highest value, deliver an economically viable technology for sustainable biochemicals production [1]. However, only limited valorization options are available; in fact, these materials are nowadays often simply considered as waste and mainly burnt as fuel for their heating value.

Furanic humins, are formed during acid-catalyzed (hydro)thermal conversion of the carbohydrate fractions of biomass, e.g. for the production of furfural and levulinate derivatives. At Avantium, they are a side product of the YXY® process. The YXY® technology catalytically converts plant-based sugar (fructose) into FDCA, the key building block for a wide range of plant-based chemicals and plastics such as polyethylene furanoate (PEF). The furanic humins are by-products of YXY® process currently producing FDCA at the pilot plant in Geleen (NL) and larger quantities are expected from the FDCA Flagship Plant in 2024 in Delfzijl (NL).

Humins are heterogeneous and polydisperse macromolecules, mainly constituted by furanic rings and aldehydes, ketones and hydroxyls as main functional groups. For many years, scientists focused on finding a way to avoid humins formation during biorefinery processes but that appears to be almost inevitable. The attention is now shifting towards ways to make high value-added products from humins to further improve the process economics of biorefineries.

An extensive analysis of the structure and pysico-chemical properties of humins was performed to demonstrate that it is possible to obtain a thermoset polymer with different properties based on the treatment used.

With the upscaling of the YXY® process, furanic humins as a new bio based side-stream, will become available in large volumes. Having the potential to form thermoset polymers furanic humins are a valuable feedstock for the adhesives market.

[1] de Jong, E., Gosselink R.J.A. (2014) Lignocellulose-based chemical products. In: "Bioenergy Research: Advances and Applications" (eds. Gupta, V.K., et. al.) Elsevier, Amsterdam, The Netherlands. pp. 277-313. ISBN: 978-0-444-59561-4.

› Close Abstract

// 11:10 – 11:35

CASHEW NUTSHELL LIQUID-BASED EPOXY RESINS: RENEWABLE OPTIONS FOR EPOXY ADHESIVES AND SEALANTS

Tom Berckmans*, Yun Mi Kim, Joe Mauck, Anbu Natesh

Cardolite Specialty Chemicals Europe N.V.; BE-Mariakerke and US-Bristol

› Show Abstract

› Close Abstract

CASHEW NUTSHELL LIQUID-BASED EPOXY RESINS: RENEWABLE OPTIONS FOR EPOXY ADHESIVES AND SEALANTS

Tom Berckmans*, Yun Mi Kim, Joe Mauck, Anbu Natesh

Cardolite Specialty Chemicals Europe N.V.; BE-Mariakerke and US-Bristol

Cashew NutShell Liquid (CNSL) is a non-food chain bio-based feedstock found in the honeycomb structure of the cashew (Anacardium Occidentale) nutshell. CNSL technology has offered versatile chemistries for developing specialty chemicals including epoxy resins and curing agents, and polyols and diols, which provides high bio-content, excellent hydrophobicity, adhesion strength, and improved thermal and mechanical properties in epoxy and polyurethane chemistry.

In this paper, novel CNSL epoxies were investigated as a partial and full substitute for BPA based epoxies in 1K and 2K epoxy formulations. CNSL epoxy resins have shown balanced performances in strengths and flexibility, excellent bonds on metals, and high water resistance properties. Utility of these CNSL bio-based epoxies includes high bio-content structural adhesives and sealants formulations, excellent durability and adhesion, and favorable labeling.

› Close Abstract

// 11:35 – 12:00

NEW ADVANCEMENTS IN THE FIELD OF MS POLYMER FOR HIGH STRENGTH / HIGH ELONGATION ADHESIVES APPLICATIONS

Nick Dewingaerden

Kaneka; BE-Westerlo-Oevel

› Show Abstract

› Close Abstract

NEW ADVANCEMENTS IN THE FIELD OF MS POLYMER FOR HIGH STRENGTH / HIGH ELONGATION ADHESIVES APPLICATIONS

Nick Dewingaerden

Kaneka; BE-Westerlo-Oevel

Through the years Kaneka has developed several types of silane terminated polyethers (known to the market as Kaneka MS Polymer™). A special and exclusive group within this polymer range are the acryl modified MS Polymer™, a blend of silyl modified polyacrylates and silane terminated polyethers.

The combination of polymers with a different chain composition and structure allows strict control on morphology, compatibility and even glass transition temperature (Tg). It results in polymers with unique properties like adhesion to plastics and dissimilar materials, combined with a high-strength level adhesion. An overview of the latest developed acryl modified polymers will be shown, together with their unique properties. With this technology a continuous progress is achieved both in polymer design and practical applications.

A range of specific case studies will be presented (e.g. High Strength adhesives, combination of High Strength / High Elongation for more demanding applications, ...).

The continuous development of these new polymer grades shows that Kaneka MS Polymer™ remains a key technology for the future and provides solutions for changing applications.

› Close Abstract

// 13:30

Welcome by Chair

Dr. Vera Haye; IVK

German Adhesives Association

Welcome by Chair

Dr. Vera Haye; IVK

German Adhesives Association

› Close Abstract

// 13:30 – 13:55

DYMAX UV TECHNOLOGY FOR PRECISION BONDING AND OPTICAL ASSEMBLY IN AUTOMOTIVE APPLICATIONS

Thérèse Hémery, PhD

Dymax; DE-Wiesbaden

› Show Abstract

› Close Abstract

DYMAX UV TECHNOLOGY FOR PRECISION BONDING AND OPTICAL ASSEMBLY IN AUTOMOTIVE APPLICATIONS

Thérèse Hémery, PhD

Dymax; DE-Wiesbaden

For many applications in automotive assembly processes, precision bonding plays a critical role. Complex optical systems like ADAS (Advanced Driver Assistance System), camera modules, sensors or adaptive front light systems have to be exactly positioned with the highest possible accuracy to ensure reliable functioning for safe driving.

This is accomplished through an Active Alignment process utilizing real-time measurements alongside light curable adhesives to fix the components in-place once positioned. While curing upon exposure to UV Broadband or LED light, the adhesive is critical towards maintaining alignment, bonding structural components, and fixing sensors, lenses or modules to the holder, barrel or PCB substrates. If necessary, a secondary heat or moisture curing step can address shadow areas. Active alignment adhesives must conform to strict technical requirements: minimal volumetric shrinkage, low CTE, rapid cure, and high Tg. Innovative Dymax UV-curable adhesives deliver on these requirements and allow for the assemblies to perform at a more demanding level as well as driving the assembly process efficiencies to significantly increase capacity and productivity whilst reduce production costs by possibly up to 30 %.

This presentation is about developing and selecting the best suitable adhesive (regarding physical and mechanical properties) for the targeted applications and optimizing the (curing) process.

› Close Abstract

// 13:55 – 14:20

CYANOACRYLATE ADHESIVES - OPENING NEW PERSPECTIVES IN ASSEMBLY WITH INSTANT ADHESIVES PRECISION DISPENSING

Peter Kraushofer & Jean-Francois Chartrel

Bostik; FR-Venette

› Show Abstract

› Close Abstract

CYANOACRYLATE ADHESIVES - OPENING NEW PERSPECTIVES IN ASSEMBLY WITH INSTANT ADHESIVES PRECISION DISPENSING

Peter Kraushofer & Jean-Francois Chartrel

Bostik; FR-Venette

For the bonding of parts with potentially small and complex geometries, the precision dispensing of the adhesive is essential to meet the bonding and sealing specifications and to respect aesthetics.

For productivity reasons, but above all of quality, the dispensing of the adhesive and the assembly of the glued parts are robotized. The desired productivity and the complexity of the parts most often require the dispensing of the adhesive with a variable flow rate at all points, which requires a volumetric system. The current volumetric systems are based on different technologies: piston pumps, gear pumps, peristaltic pumps or even by progressive cavity pumps, subject of this publication.

The problem becomes difficult when it comes to cyanoacrylates reacting extremely quickly in the absence of gap. In the specific case of progressive cavity pumps, the polymerization of the adhesive between rotor and stator causes at least a very audible “creak, in the worst case, destruction of the stator.

To solve the problem of rapid polymerization of cyanoacrylates in such volumetric dosing systems we have imagined a permanent oscillation movement of the rotor between two dispensing sequences. The computing management of the rotor allows also the dispensing of beads of different widths on the same part, and the production of bead of controlled geometry from the beginning (to avoid overflow at start-up) to the end in particular with the possibility of "suction- back”. This controlled management allows the dispensing of a closed bead (Loop) without visible junction. The knowledge acquired in monocomponent Cyanoacrylates can be transposed to the bicomponent systems. "High viscosity" and a fortiori "Gel" grades are more suitable for precision dispensing, such as the dispensing of beads not exceeding 0.3 mm in width.

ViscoTec, one of the leaders with this type of dosing system, in mono and bi-component, has supported this development with its valuable advices and unshakable support. The work of selecting the best grade of elastomer was an important point of the project with the oscillation concept, one does not go without the other.

› Close Abstract

// 14:20 – 14:45

SUSTAINABILITY IN THE DIGITAL DEVELOPMENT PROCESS

Tobias Bodenmüller

medmix Switzerland AG; CH-Haag

› Show Abstract

› Close Abstract

SUSTAINABILITY IN THE DIGITAL DEVELOPMENT PROCESS

Tobias Bodenmüller

medmix Switzerland AG; CH-Haag

Over the last decades, the application of 2K-adhesives has been on the rise across various industries. With emergence of increasing use of plastics and disposal challenges, the quest for more effective material and reliable dispensing systems continues. Along the process chain, the assessment of environmental impacts will be a crucial element in successful application of 2K-adhesives and performance indicators in the future. As a leading manufacturer of 2K-component mixing and application systems, medmix already uses different simulation methods in the product development. We have now supplemented these with eco design principles to enable the best solution for our customers.

The article will cover what are medmix`s sustainability goals in response to the changing framework conditions and how they are integrated into our development process. Beside several simulation technologies (injection molding, structural and fluid flow) we have now implemented life cycle analysis to calculate the ecological footprint of our products. Examples for a functional packaging which includes the interaction of different aspects will be in introduced and discussed.

› Close Abstract

// 14:45 – 15:15

PROCESS COMPARISON OF VISCOUS ADHESIVE AND SEALANT PRODUCTION

Patrik Thoma

fitech ag; CH-Amriswil

› Show Abstract

› Close Abstract

PROCESS COMPARISON OF VISCOUS ADHESIVE AND SEALANT PRODUCTION

Patrik Thoma

fitech ag; CH-Amriswil

The production of adhesives is characterised by high attention to process quality, variability, production speed, cleaning time, energy consumption, environmental impact and safety.

These requirements must be implemented in production at different operational levels: manual, semi-automatical or fully automatical.

A process comparison shows possibilities for the current configuration and alternatives in the equipment mix.

› Close Abstract

// 15:15 - 15:45

Refreshment Break

// 15:45 – 16:10

STRUCTURAL MONITORING OF ADHESIVELY STRENGTHENED STEEL STRUCTURES WITH DISTRIBUTED FIBREOPTIC SENSORS

Hinrich Grefe

University of Braunschweig / Institute of Joining and Welding; DE-Braunschweig

› Show Abstract

› Close Abstract

STRUCTURAL MONITORING OF ADHESIVELY STRENGTHENED STEEL STRUCTURES WITH DISTRIBUTED FIBREOPTIC SENSORS

Hinrich Grefe

University of Braunschweig / Institute of Joining and Welding; DE-Braunschweig

Adhesively bonded steel patches are used to repair and strengthen bridges or other engineering structures. With the additional layers of adhesive and steel upon the original structure, monitoring becomes rather difficult. Distributed fibreoptic sensors can provide a detailed look inside those layers and measure the local deformation; from that, the current condition of the structure and the bondline can be determined.

› Close Abstract

// 16:10 – 16:35

THE DIGITAL MONITORING OF BONDING PROCESS PARAMETERS

Marco Rodriguez

as adhesive solutions e.K.; DE-Dreieich

› Show Abstract

› Close Abstract

THE DIGITAL MONITORING OF BONDING PROCESS PARAMETERS

Marco Rodriguez

as adhesive solutions e.K.; DE-Dreieich

Adhesive processes are becoming more and more complex, which means that the probability of failure will also increase in the near future. However, since adhesive bonding is a joining method that is becoming increasingly popular, it is becoming more important to keep the processes under control.

However, this can only be achieved if process data is recorded and evaluated. Data such as temperature and humidity can influence bonding processes and should be constantly monitored in order to be able to react in case of deviations.

The digital recording and evaluation of such parameters is an important step in the right direction. Regardless of whether manual or automated processes are used, the issue of traceability is a focus topic. The current situation of manual documentation is no longer up to date and must be discontinued. APP and cloud-based systems can help here.

› Close Abstract

// 16:35 – 17:00

ADHESIVE BONDING 4.0: IMPLEMENTATION OF UNIFIES COMMUNICATION STANDARD IN THE ADHESIVE BONDING PRODUCTION

Ivo Neumann

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM; DE-Bremen

› Show Abstract

› Close Abstract

ADHESIVE BONDING 4.0: IMPLEMENTATION OF UNIFIES COMMUNICATION STANDARD IN THE ADHESIVE BONDING PRODUCTION

Ivo Neumann

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM; DE-Bremen

Successfully digitised adhesive bonding technology is not only based on the necessary use of sensors, cameras, controllers and computers, but also requires the standardisation of the associated data communication. In the publicly funded project "Adhesive Bonding 4.0", this standardisation is being developed for the field of adhesive bonding technology with the participation of the industry for commercially available adhesive application systems.

› Close Abstract

// 18:30

Networking Dinner

Wednesday, February 15, 2023

// 08:30

Welcome by Chair

Elisabeth Stammen

University of Braunschweig

Welcome by Chair

Elisabeth Stammen

University of Braunschweig

› Close Abstract

// 08:30 – 08:55

QUALITY ASSURANCE OF SURFACES PRIOR TO ADHESIVE BONDING

Univ.-Prof. Dr.-Ing. Paul Ludwig Geiß

RPTU University of Kaiserslautern-Landau, Workgroup Materials and Surface Technologies; DE-Kaiserslautern

› Show Abstract

› Close Abstract

QUALITY ASSURANCE OF SURFACES PRIOR TO ADHESIVE BONDING

Univ.-Prof. Dr.-Ing. Paul Ludwig Geiß

RPTU University of Kaiserslautern-Landau, Workgroup Materials and Surface Technologies; DE-Kaiserslautern

The quality of adherent surfaces prior to adhesive bonding has a strong impact on the bond performance in terms of strength and durability. The in-line quality control of cleaning and pre-treatment processes thus pursues the goal of monitoring the suitability of the surface to be bonded. Spectroscopic analysis methods are advantageous because they may be applied in a non-destructive manner. In addition to identifying and quantifying contaminations, IR spectroscopy also allows the detection of adhesion promoters, activators and primers. In these cases, process-integrated IR analysis can be used to verify the desired activation effect.

The range of FTIR analyzers available today extends from modular industrial instruments to hand-held mobile small spectrometers. High surface sensitivity is provided by measuring devices that use the grazing angle principle for the infrared analysis of superficial contaminations. In this talk, the performance of devices for diffuse reflectance (DRIFT), grazing angle (GA) and attenuated total reflectance (ATR) will be compared.

To determine the limit of detection (LOD) required for quality assurance, the influence of surface contaminations on the quality of adhesively bonded joints is first investigated experimentally using destructive mechanical testing methods and expressed as a quality parameter. When the chosen spectroscopic method meets the requirements of the detection limit, the result of the surface analysis can be used to infer whether the quality of the joint to be bonded is likely to meet the requirements. Assessment routines such as the FTIR spectroscopic integration methods can be tailored to a production-relevant issue and thus be implemented in a quantity-specific manner. By using process-integrated handheld FTIR tools for non-destructive surface analysis, adhesively bonded joints with poor quality can be avoided.

› Close Abstract

// 08:55 – 09:20

OPENAIR® PLASMA TECHNOLOGY FOR WETTING SEALING AND BONDING IN BATTERY APPLICATIONS

Klaus Kresser

Plasmatreat Schweiz AG; CH-Diepoldsau

› Show Abstract

› Close Abstract

OPENAIR® PLASMA TECHNOLOGY FOR WETTING SEALING AND BONDING IN BATTERY APPLICATIONS

Klaus Kresser

Plasmatreat Schweiz AG; CH-Diepoldsau

Why is it beneficial to use OpenAir® technology for wetting sealing and bonding in battery applications? For these applications a lot of different substrates made of metals and plastics are used for gluing and coating applications. This means that for the actual function - such as adhesion, corrosion protection, etc. efficient and environmentally friendly inline treatment solutions are needed. In addition, with every new car model, new battery designs are established and new legislations have to been taken into account. For this a universal and flexible treatment system is preferred.

Here, OpenAir®-Plasma technology simplifies the processes. All different types of materials like plastic, glass, metals like aluminum, etc. can be treated with OpenAir®.Plasma. This process is already being used successfully for surface treatments in a large number of different automotive battery applications and for other industries and applications. Herewith OpenAir®-Plasma technology assure long-term adhesion.

In the paper, the following topics will be introduced and discussed:

- Explanation of the basic principle of the OpenAir®-Plasma treatment on plastic and metals.

- Distinction between different plasma technologies: Activation of surfaces and coating of surfaces via PECVD (Plasma Enhanced Chemical Vapor Deposition).

- Examples of substrate/adhesive combinations, where PECVD can be used for automotive battery applications.

- Examples of successful implementation and industrialization of green processes and new materials with PECVD technology.

- Examples Lean pre-treatment solutions for bonding are industrialized.

› Close Abstract

// 09:20 – 09:45

GAP FILLING EFFICIENCY OF ADHESIVE SEALANTS

Dr. Martin Brandtner-Hafner

Fracture Analytics; AT-Mörbisch am See

› Show Abstract

› Close Abstract

GAP FILLING EFFICIENCY OF ADHESIVE SEALANTS

Dr. Martin Brandtner-Hafner

Fracture Analytics; AT-Mörbisch am See

The performance of adhesive joints depends on a variety of influencing factors. These include external aspects, such as load type, load dynamics, and environmental influences, as well as internal ones, such as adhesive gap, adhesive surface, geometric shape, and substrate type. However, for adhesive selection, economic facet also plays a major role in addition to technical parameters. Hence, this technical paper will focus on the influencing design parameter "gap filling efficiency" from a techno-economical point of view. This is accomplished by utilizing holistic fracture analysis with an innovative empirical evaluation approach. Since the fundamental principle of characterizing gap filling performance is not explicitly defined in the manufacturer`s technical data sheets, FRACTURE ANALYTICS has developed an empirical in-house test standard, the so-called MCT method. It sets higher requirements than applied in the adhesive industry leading to superiority over standardized mechanical test setups, such as lap-shear, pull-off, tearing, and peel-off. The reason to this is they fully ignore interface damaging effects of adhesive joints and only apply stress-based, single-parameter failure criteria leading to results of limited significance. In this study, MCT is executed on different adhesive sealants for structural glazing to examine their gap-filling efficiency. The results reveal that both bonding efficiency and bonding costs vary greatly with a changing gap of the bonded joint. That is why the introduction of a novel evaluation parameter called gap filling efficiency allows empirically valid statements to be made about the adhesive bonding optimum incorporating bonding costs, bonding efficiency, and interfacial bonding safety. For the adhesive engineer, designer, and practitioner, this represents a powerful selection tool fostering the best design of an adhesive joint.

› Close Abstract

// 09:45 - 10:15

Refreshment Break

// 10:15 – 10:40

SIKAPOWER-800 – FAST CURING AND INJECTABLE EPOXY ADHESIVE

Tobias Illi

Sika Technology AG; CH-Zürich

› Show Abstract

› Close Abstract

SIKAPOWER-800 – FAST CURING AND INJECTABLE EPOXY ADHESIVE

Tobias Illi

Sika Technology AG; CH-Zürich

Two component epoxy adhesives are widely used in the wind industry. For the production of wind turbine blades, bonding pastes (tough and structural epoxy adhesives) are used to durably bond the blade parts together. Besides that, epoxy adhesives are also in use for the repair in various applications along the blade and its manufacturing process.

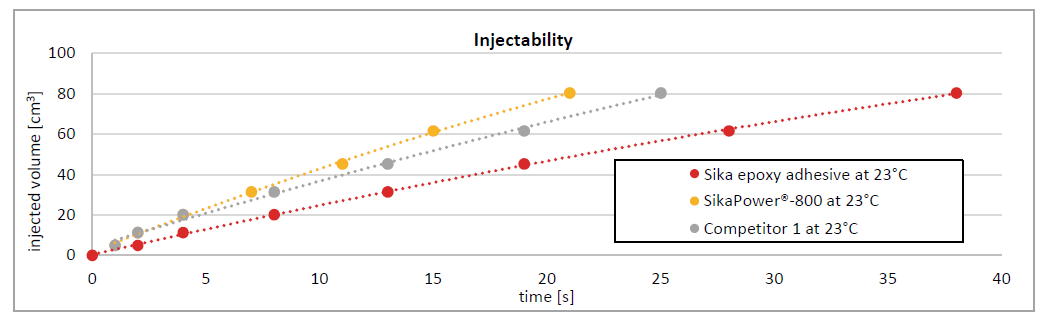

Figure 1. Injectability properties of SikaPower®-800 in comparison with competitor adhesive (2C acrylate) and a current Sika epoxy adhesive for wind blade bonding applications

Figure 1. Injectability properties of SikaPower®-800 in comparison with competitor adhesive (2C acrylate) and a current Sika epoxy adhesive for wind blade bonding applications

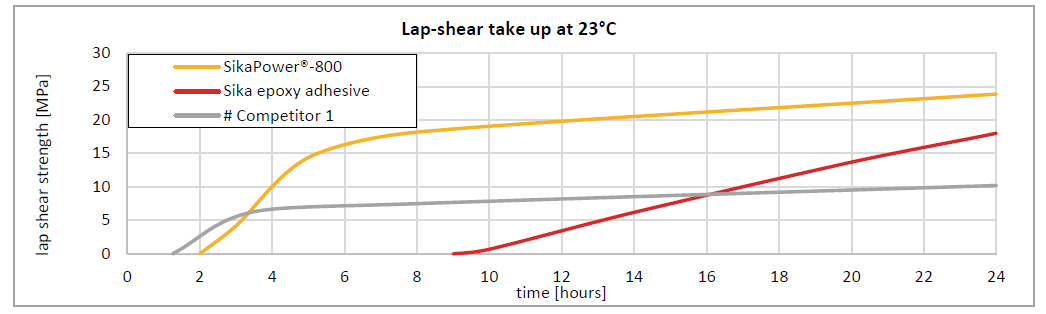

Customers expect that the adhesive solution selected to repair voids or dis-bonds of the main bond has the same final properties as the original blade bonding paste. However, the properties that make bonding pastes suitable for manufacturing large composite structures, such as long open time, high sag resistance and relatively long thermal curing profiles, are not suited for repair injection where low viscosity and full room temperature curing capability at low shrinkage are beneficial or preferred. It is therefore inevitable that an alternative to the blade bonding adhesive is required for injection bonding and ideally, it should have as similar properties as possible in the other areas. Sika has developed SikaPower®-800, a low-shrinkage epoxy repair injection adhesive that is chemically identical to current blade bonding adhesives. It offers very similar mechanical properties, a higher toughness to resist cracking and can also fully cure without the need external heating.

Figure 2. Lap shear strength uptake of SikaPower®-800 in comparison with competitor adhesive (2C acrylate) and a current Sika epoxy adhesive for wind blade bonding applications

Figure 2. Lap shear strength uptake of SikaPower®-800 in comparison with competitor adhesive (2C acrylate) and a current Sika epoxy adhesive for wind blade bonding applications

› Close Abstract

// 10:40 – 11:05

NEW DEVELOPMENTS OF EPOXY ADHESIVES

Dr. Davide Malinverno

ELANTAS Europe S.r.l.; IT-Collecchio

› Show Abstract

› Close Abstract

NEW DEVELOPMENTS OF EPOXY ADHESIVES

Dr. Davide Malinverno

ELANTAS Europe S.r.l.; IT-Collecchio

In an entire production process, sometimes, the right selection of an adhesive could be an underestimated aspect due to the small amount used in the process. In truth, it hides a combination of sciences as chemistry, physic and engineering that must be combined to design and select the right product for the right application.

In modern technology, adhesives are replacing more and more classical bind process such as welding and joining. Building and construction industry had been first in using adhesives and sealants, followed by the composite industry. Today these types of materials are also a standard tool in automotive, nautical and many other industries, even in applications relevant for safety.

A multitude of applications and different processes must require a broad range of products.

In this lecture will be shown some insights about new development of Epoxy-amines adhesives dedicated to marine industry, winding blades, and automotive industry, where the combination of rheological properties and mechanical performances play a strategic role for the selection of the right product.

› Close Abstract

// 11:05 – 11:30

BIOBASED TOUGHNESS

Sven Wiemer

Schill+Seilacher "Struktol" GmbH; DE-Hamburg

› Show Abstract

› Close Abstract

BIOBASED TOUGHNESS

Sven Wiemer

Schill+Seilacher "Struktol" GmbH; DE-Hamburg

Epoxies are inherently high strength but also brittle. In order to formulate a ductile, mechanically loadable epoxy-based system such as structural adhesives or fiber composite matrices, impact modifiers (tougheners) are required. In the case of structural adhesives, as used in modern body-in-white construction, where they represent the current standard of joining technology, crash-proof passenger compartments can be produced by joining components over the entire bonding area, which would not be achievable by spot welding alone.

The tougheners required for this are usually based on petrochemical precursors and substances. The most frequently encountered impact modifiers are epoxy resins (adducts) modified with CTBN (rubber) along with blocked polyurethanes. In addition, biobased epoxy resin adducts or those based on renewable raw materials have also been formulated for years. The most common are dimer fatty acids, as used by Struktol in the adduct Polycavit 3632, which can be described as quasi-sustainable resins before this definition became widely used.

Currently under development at Struktol is an epoxy resin adduct based on a bio-based polyester originally developed for classical UPE applications. However, first iterations show that tougheners based on this UPE have already shown promising results, which encourage us to further develop in this direction of a sustainable product.

Today we would like to give an interim summary as well as an outlook on the new type of impact modification, which is not exclusively based on the idea of sustainability, but rather on the further development and combination possibility(s) of chemistry.

› Close Abstract

// 11:30 – 12:00

PHYSICAL MIXING OF WATERBORNE POLYURETHANE AND NANOSILICA DISPERSION. IS IT A FEASIBLE STRATEGY FOR IMPROVING THE PROPERTIES OF WATERBORNE POLYURETHANE ADHESIVES?

Prof. José Miguel Martín Martínez*, M. Echarri-Giacchi

University of Alicante | Adhesion and Adhesives Laboratory; ES-Alicante

› Show Abstract

› Close Abstract

PHYSICAL MIXING OF WATERBORNE POLYURETHANE AND NANOSILICA DISPERSION. IS IT A FEASIBLE STRATEGY FOR IMPROVING THE PROPERTIES OF WATERBORNE POLYURETHANE ADHESIVES?

Prof. José Miguel Martín Martínez*, M. Echarri-Giacchi

University of Alicante | Adhesion and Adhesives Laboratory; ES-Alicante

Waterborne polyurethane dispersions (PUDs) are multiphasic systems made of spherical nanoparticles dispersed in water. PUDs are synthesized by reacting a diisocyanate, a polyol, an internal emulsifier and a chain extender, the internal emulsifier anchors covalently pendant ionic or non-ionic moieties in the linear polyurethane chain which are oriented outside of the particles in the presence of water. Although effective, the waterborne polyurethane adhesives have limited water resistance, relative low thermal resistance and insufficient mechanical properties. For improving these properties, several strategies have been proposed including the addition of cross-linkers and fillers, among other.

Fumed silica fillers have been commonly added for improving the rheological, mechanical and adhesion properties of the solvent born polyurethane adhesives. However, the addition of fumed silicas to PUDs is not effective due to the formation of silica agglomerates and the phase separation of the polyurethane micelles. Therefore, different procedures have been proposed for incorporating silica fillers in PUDs, including the sol-gel method, the in-situ polymerization of the silica precursor, and the physical mixing of the PUD and nanosilica dispersions, among other. Although the incorporation of silica precursors during the polyurethane synthesis is efficient for producing hybrid silica-waterborne polyurethane dispersions, their stabilities and adhesion properties are limited, the physical mixing of the PUD and nanosilica dispersions is more simple, this procedure has been selected in this study.

Nanosilica dispersion was added to waterborne polyurethane dispersion by using three different physical mixing procedures differing in the flow regime (tangential, laminar, radial) and the stirring rate (300-2400 rpm). The influence of the physical mixing procedure on the structural, thermal, rheological, mechanical, surface and adhesion properties of the polyurethanes (PUs) containing 1 wt.% nanosilica was evaluated. The nanosilica in the dispersion was functionalized with acrylic moieties and showed high surface tension and negative Z potential values. The PU+nanosilica blend made with higher shear rate and laminar flow regime showed high homogeneous dispersion of the nanosilica particles and greater extent of intercalation between the soft segments of the polyurethane, this led to higher thermal stability. Unexpectedly, the better dispersion of the nanosilica in the PU matrix decreased the wettability of the PU+nanosilica materials due to the migration of acrylic moieties from the nanosilica particles to the surface. As a consequence, a decrease of the final T-peel strength was found. However, the single lap-shear strength did not change by adding nanosilica because of the scarce improvement of the mechanical properties in the PU+nanosilica materials.

Acknowledgment. This study was partially supported by the Research Vice-president Office (Vicerrectorado de Investigación) of the University of Alicante (grant no. AII21-07

› Close Abstract

// 13:30

Welcome by Chair

Univ.-Prof. Dr.-Ing. Paul Ludwig Geiß

University of Kaiserslautern

Welcome by Chair

Univ.-Prof. Dr.-Ing. Paul Ludwig Geiß

University of Kaiserslautern

› Close Abstract

// 13:30 - 13:55

CONTROLLING ADHESION AT THE MOLECULAR LEVEL – NEW MULTIFUNCTIONAL ORGANOSILICON ADDITIVES AND RESINS FOR FUNCTIONAL ADHESIVES

Dr. Matthias Koebel

siloxene AG; CH-Brüttisellen

› Show Abstract

› Close Abstract

CONTROLLING ADHESION AT THE MOLECULAR LEVEL – NEW MULTIFUNCTIONAL ORGANOSILICON ADDITIVES AND RESINS FOR FUNCTIONAL ADHESIVES

Dr. Matthias Koebel

siloxene AG; CH-Brüttisellen

Adhesive technology relies on curing of a resin to create a strong cohesion of the adhesive layer and good interfacial adhesion the the bonding subtrate(s). Typical raw materials comprised in commercial adhesives have been standardized and innovation in this sector is limited. Here we propose the use of a new class of multifunctional dendrimer silanes – so-called Q-T polysiloxane resins – to drive new solutions in the adhesives sector.

siloxene products offer tailorable chemical functionality, minimal eco impact and are solvent-free, non-flammable low-viscous raw materials. XenCure products come in a range of single or multi-functional dendrimer silanes, with selectable amino, glycidoxy, methacryloxy, vinyl chemistries. They can be thought of as a “silane 2.0” and are typically used as additives, offering superior adhesion and crosslinking properties compared to standard monomer silanes. XenRes products are hybrid dendrimers with grafted commodity resin chemistry, covering all standard resin types such as bisphenol A epoxy, isocyanate, UV curable (meth)acrylate and silane terminated polymer (STP). These are used as co-resins, boosting adhesion on certain substrates and altering curing mechanism, speed and also mechanical properties.

At siloxene we are developing this innovative raw materials platform for a variety of technological applications with focus on structural adhesives, multi-cure chemistry and adhesion profile control. Examples will highlight some of the unique properties the concept has to offer.

› Close Abstract

// 13:55 – 14:20

NON-ISOCYANATE POLYURETHANES (NIPUs): A PROMISING PATHWAY TOWARDS SUSTAINABLE AND ENVIRONMENTALLY FRIENDLY ADHESIVES

Dr. Vincent Lutz

nolax AG; CH-Sempach Station

› Show Abstract

› Close Abstract

NON-ISOCYANATE POLYURETHANES (NIPUs): A PROMISING PATHWAY TOWARDS SUSTAINABLE AND ENVIRONMENTALLY FRIENDLY ADHESIVES

Dr. Vincent Lutz

nolax AG; CH-Sempach Station

Polyurethanes are widely used in a whole range of products in our daily life thanks to their large material portfolio, excellent properties, and versatility.

Due to REACH regulations and the use of hazardous isocyanates, nonisocyanate polyurethanes (NIPUs) have gained interest over the past decade. One of the most promising routes is the use of the polyaddition of different cyclic carbonates with polyamines to form polyhydroxyurethane (PHU) polymers.

Nevertheless, the availability of cyclic carbonates as raw material and their low reactivity at room temperature with polyamines remain quite challenging today.

Starting with a brief description of several routes investigated to synthetize PHU to overcome this limitation, new reactive systems are successfully cured at room temperature. Moreover, the resulting nonisocyanate polyurethane-based networks demonstrate a large variety of mechanical, thermo-mechanical and adhesion performances. This enables obviously a broad panel of candidates for a new class of sustainable and environmentally friendly adhesives in future.

› Close Abstract

// 14:20 – 14:45

SUSTAINABLE DEVELOPMENT IN ADHESIVES: DESIGN OF NEW MONOMERS AND FORMULATIONS, MANAGEMENT OF WASTES

Luigi Mora

Vinavil SpA; IT-Villadossola

› Show Abstract

› Close Abstract

SUSTAINABLE DEVELOPMENT IN ADHESIVES: DESIGN OF NEW MONOMERS AND FORMULATIONS, MANAGEMENT OF WASTES

Luigi Mora

Vinavil SpA; IT-Villadossola

The common accepted definition of sustainability is “meeting the needs of the present without compromising the ability of future generations to meet their own needs”.

In the last decades, Vinavil has improved its business to reach the quality and sustainability goals such as the removal of Substances of Very High Concern from our product formulas (ex: APEO, Boron, etc..) and the elimination/reduction of hazardous substances (like acetaldehyde, formaldehyde) as well as VOCs / SVOCs.

As a part of the EU Green Deal, chemical strategy for sustainability is a fundamental pillar dealing with research & innovation for chemicals and safe & sustainable by design criteria. Following this view, Vinavil, in collaboration with Florence University, has started a project for the design and polymerization of new monomers derived from biomasses.

Carbohydrates from waste sources have been derivatized using an unsaturated reactant, to be suitable to be used in radical polymerizations. The aim of this strategy is to introduce in some vinyl adhesives components obtained from renewable sources, in alignment with the increasingly frequent requests from some important industrial groups of adhesives containing biobased materials.

Vinavil is also going to launch in the DIY market a new line of adhesives sustainable and certified.

Further, various projects about polymeric waste sludges reuse are ongoing.

› Close Abstract

// 14:45 – 15:15

RECYCLING ADHESIVES – A TECHNOLOGICAL OXYMORON?

Dr. Hartmut Henneken

Jowat SE; DE-Detmold

› Show Abstract

› Close Abstract

RECYCLING ADHESIVES – A TECHNOLOGICAL OXYMORON?

Dr. Hartmut Henneken

Jowat SE; DE-Detmold

What opportunities are there for an adhesive manufacturer to align its own business more closely with a circular economy? Can adhesives be recycled and reused as adhesives after the end-of-life of their first application? What are the most viable ways to develop adhesives that are recycling-friendly? Does biodegradability make sense as a route to return products into the natural cycle? There are many fundamental questions of a strategic & technological nature. It is absolutely clear that the adhesives industry and their supply chain (as well as the whole industry, also on a global scale) needs to develop new processes / products that can avoid the use of "fresh" fossil carbon sources as much as possible (ideally not needing any at all). Technology development for this has been ongoing for many years. Predictions about the required future "carbon mix" (as a linguistic analogue to the energy mix) vary, but more or less only with respect to the ratio of the material origin of the carbon atoms, which we namely still need and will continue to need undiminished as unavoidable basic building blocks of life and most materials. Contrary to the field of energy use, it is therefore obviously not possible to decarbonize the material supply. The origin of the raw material/feedstock has to be changed in order to use sustainable technologies and resources. Basically, three pillars are identified to serve as future carbon sources: Direct CO2 use, bio-based feedstocks, and recycled "waste"/valuable materials as feedstocks. This presentation will attempt to answer some of the above questions. Examples from Jowat Research & Development will be shown to illustrate where the adhesives industry stands today when it comes to the idea of recycling and the circular economy in general.

› Close Abstract